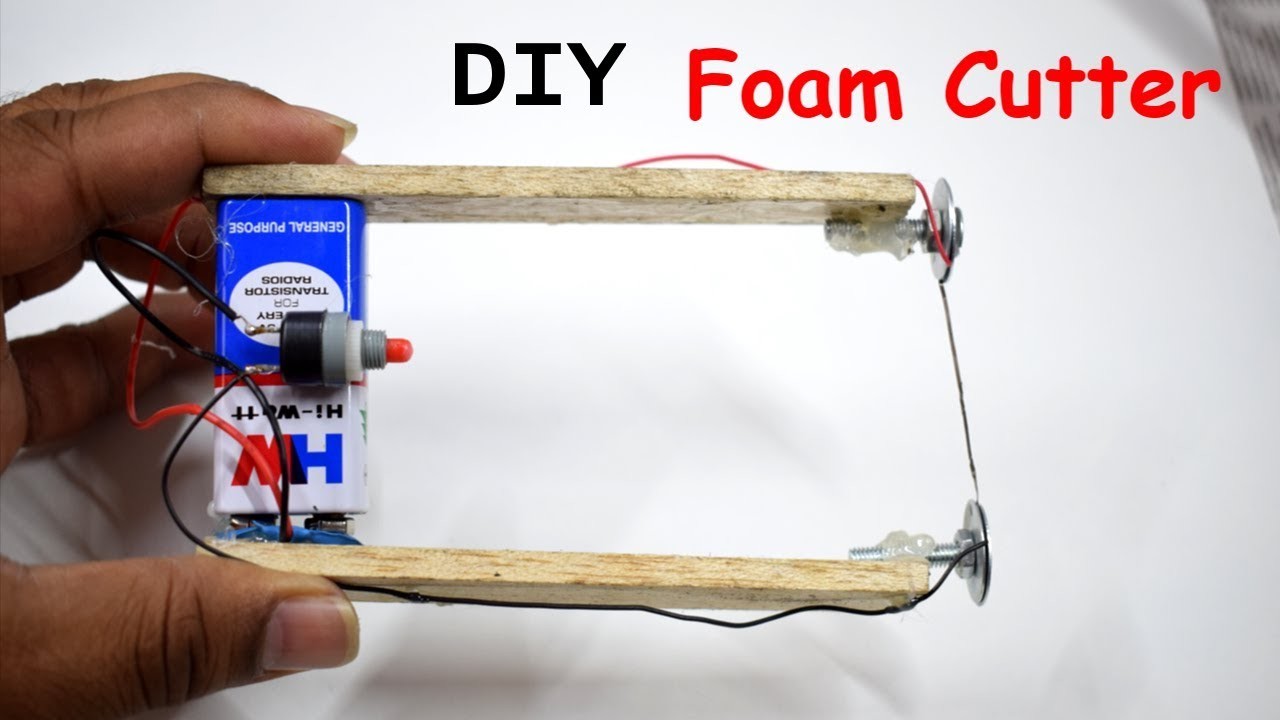

Cheap Wires For Foam Cutting

Unveiling the Adaptability of CNC Warm Wire Foam Trimming Machines Introduction: CNC hot wire polyurethane foam cutting machines enhance the process of shaping and making foam materials, giving versatility and accurate for a wide range of programs. In this article, we delve straight into the essential info on these cutting-edge machines, exploring their employs, components, features, and even pricing. Uses and Applications: Foam Types: CNC hot wire foam cutters are generally indispensable tools with regard to cutting various polyurethane foam types, including expanded polystyrene (EPS), extruded polystyrene (XPS), plus expanded polypropylene (EPP). They find programs in industries including insulation and manufacturing to signage, statues, and aerospace. New and Industrial Apps: These machines are used for cutting architectural shapes, packaging components, building components, as well as intricate 3D varieties seen in design parks and video sets. Components plus Features: Software: COMPUTER NUMERICAL CONTROL foam cutters are equipped with style software for producing shapes and slicing software for managing the machine. The particular tensioning mechanism assures optimal wire tension for precise reduces.  Cutting Capacities: Powerful cutting sizes intended for horizontal, vertical, and even wire length, alongside with the quantity of axes, identify the machine's versatility in cutting various shapes, including pointed structures. Production Performance: Features such as numerous wires, extended successful wire length, and even cutting speed command enhance production productivity, catering to varied cutting requirements. Charges and Considerations: Price Range: CNC foam cutters vary extensively in price, ranging from $1500 to be able to $50, 000, relying on factors such as machine size, quantity of wires, and tensioning mechanisms. Foam Finish: Understanding foam layer techniques, including priming and coating using epoxy or polyurethane, ensures durability and even suitability for art work and finishing. Trimming Techniques: Hot Line Cutting: Utilizing heated nichrome wires, sizzling wire foam blades vaporize foam along with precision, yielding easy cuts ideal intended for architectural models, signage, and industrial software. Manual Cutting: Standard foam cutting approaches involve manual decreasing with water-dipped blades at specific angles to achieve desired outcomes, well suited for smaller-scale assignments and manual healthy diet. Conclusion: CNC very hot wire foam reducing machines represent the cutting-edge solution for shaping foam supplies with precision in addition to efficiency. From Foam Cutting Wires to professional production, these flexible machines offer unrivaled flexibility and reliability, thus, making them indispensable resources across various sectors. Understanding their employs, components, features, in addition to pricing enables educated decision-making when looking for the right equipment for specific trimming needs.

Cutting Capacities: Powerful cutting sizes intended for horizontal, vertical, and even wire length, alongside with the quantity of axes, identify the machine's versatility in cutting various shapes, including pointed structures. Production Performance: Features such as numerous wires, extended successful wire length, and even cutting speed command enhance production productivity, catering to varied cutting requirements. Charges and Considerations: Price Range: CNC foam cutters vary extensively in price, ranging from $1500 to be able to $50, 000, relying on factors such as machine size, quantity of wires, and tensioning mechanisms. Foam Finish: Understanding foam layer techniques, including priming and coating using epoxy or polyurethane, ensures durability and even suitability for art work and finishing. Trimming Techniques: Hot Line Cutting: Utilizing heated nichrome wires, sizzling wire foam blades vaporize foam along with precision, yielding easy cuts ideal intended for architectural models, signage, and industrial software. Manual Cutting: Standard foam cutting approaches involve manual decreasing with water-dipped blades at specific angles to achieve desired outcomes, well suited for smaller-scale assignments and manual healthy diet. Conclusion: CNC very hot wire foam reducing machines represent the cutting-edge solution for shaping foam supplies with precision in addition to efficiency. From Foam Cutting Wires to professional production, these flexible machines offer unrivaled flexibility and reliability, thus, making them indispensable resources across various sectors. Understanding their employs, components, features, in addition to pricing enables educated decision-making when looking for the right equipment for specific trimming needs.